Overview

One of the most frequently asked questions today by innovators and entrepreneurs looking to design the perfect consumer comfort product is: can I power my gadget with a battery? This post will help you understand the requirements and challenges of using battery power to run your heated device. It all boils down to the questions how big, how hot and how long? Since the choices for batteries are virtually limitless, the purpose of this post is to arm you with the primary information you must have in order to consult a battery specialist, who can help you with your selection.

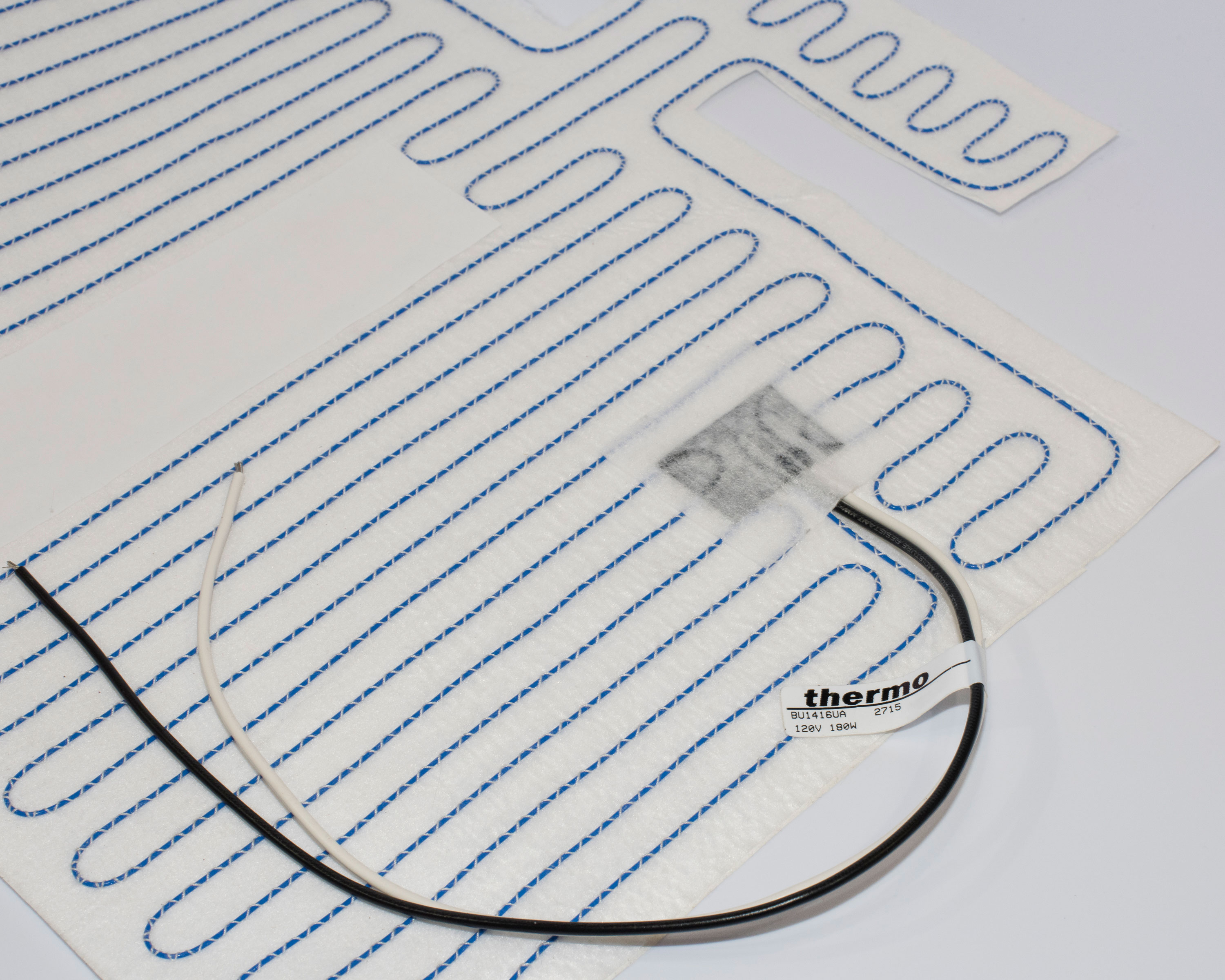

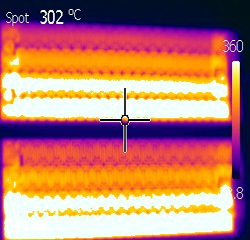

Let’s review the basics. Heat generation is a function of watt density, ambient conditions and thermal losses (or gains). Watt density is the amount of wattage produced divided by the area producing the wattage, referred to most frequently as watts per square inch.

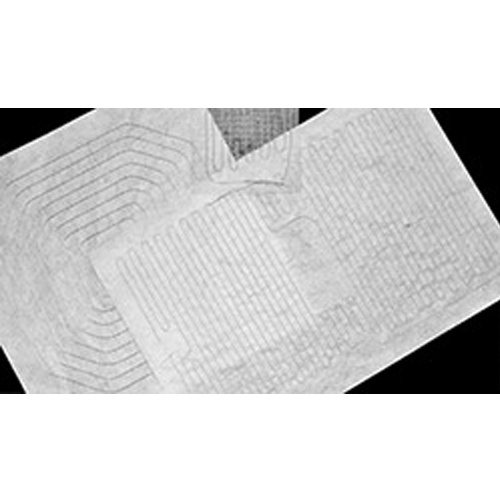

A real world example: I’ve developed a mobile warming tray and now I want to sell it to Michigan fans for football games. The tray is 8 inches x 8 inches and uses polymer thick film heater technology. I want the heater to get to about 165°F and be able run for about two and a half hours. It will be insulated, have a thermostat and needs to run off a battery. What now?

STEP 1 – Set a target temperature

When it is all said and done, establishing the maximum operating temperature of the item you are designing is the primary driver in evaluating your options. You don’t need to be dead on with this, but the more variables you consider, the more accurately you will be able to predict the outcome. Will there be thermal influences such as insulation, air flow, or large thermal masses adding or taking away from the heater’s capabilities?

For our example, let’s choose a comfortable operating temperature of 60 Degrees

STEP 2 – Estimate the Wattage

After you have determined the temperature you would like to achieve in your device, you can determine the watts per square inch that you will require by conducing some simple tests (refer to our blog post “How to determine the watt density required in my application” for instructions on conducting a simple test for this).

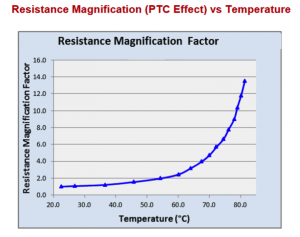

Another way to get a very general idea about what the wattage you may need is to look at the chart below, select a desired operating temperature and note the corresponding watt density. Note that the chart depicts heat output in open air on aluminum, so consider your environment and adjust accordingly.

Our Heated Seat Cushion will be insulated by the cushion from below (suggesting a lower watt density may be acceptable) and controlled by a thermostat (suggesting a higher watt density may be acceptable for rapid heat-up) so we’ll split the difference and begin our testing with the standard baseline for 60 degrees F. Looking at the chart below, 60F corresponds to approximately 0.5 watts per square inch.

Wattage calculation

8 IN x 8 IN = 81 SQ IN

64 SQ IN x 0.75 WPSI = 48 WATTS (estimated to achieve 165 degrees F in the application).

STEP 3 – Understanding Amp-hours

Determining the continuous load, or wattage, that is required is most of the battle, so now that we have a process for that, we can move on to preparing for our conversation with a battery specialist. Much like the term “watt-density” is used by heater designers, the term used in the battery world is “amp-hours.” An amp-hour is a unit of measurement used to express a battery’s capacity over time. This is calculated by multiplying the current flow (in amps) by the discharge time (in hours).

In order to be able to calculate the amperage for our battery, you will be asked to settle on a voltage. Good news! Heaters can be designed to very wide range of voltages.

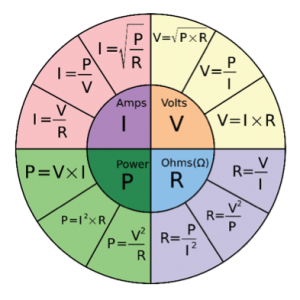

In our example, we’ll specify a 12V battery as a starting point. Remembering that wattage (P) is equal to voltage (V) times current (I)

P = V x I or I = P/V

I = 48 watts / 12 volts

I = 4 amps

Logic would suggest that a 12V battery with a 10 aH rating would last about 2.5 hours when the load is drawing 4 amps, correct? Well, that’s sort of true. There are things called temperature fluctuation and Peukert’s Law that says this is not exactly true – but we’ll leave the details of this subject to the battery experts. Suffice it to say that you can always count on the battery lasting shorter than you anticipate…

STEP 4 – Consult a Battery Specialist

This is where the process gets interesting and you will need to consult with a battery specialist to determine the best combination of size, voltage and endurance for your application. Be prepared to discuss:

- The size of the space available for the battery

- The wattage you calculated above

- Voltage options that work for you and your controlling devices (if necessary)

- The minimum endurance (in hours) that you need the battery to produce.

There are thousands of combinations and technologies available, so now that you are armed with the information you need to provide your battery specialist, selecting the right battery should be much easier. If you would like to discuss your application requirements further, please call to speak to one of our Application Engineers at 864-295-4811.