Whether you are the Chief Product Development Engineer for a Fortune 500 company or an Entrepreneur with a great idea for a heated finished product, determining what you need from your heater can be a daunting task. Fortunately, it doesn’t have to be that way. Below we will outline the steps necessary for the most time and cost effective method to answer the fundamental question about heating elements – what wattage will I need in my application?

Before we begin, it is important to note that Watt density is the central concept upon which flexible heaters are selected, designed and perform. Watt density is simply the wattage output of a heater relative to its size, typically expressed in the US in watts per square inch (wpsi). For example, a 10 inch by 10 inch heater which is 200 watts would have a watt density of 2 wpsi. All things being equal, the watts per square inch is the primary influence that determines the heaters operating characteristics in your application.

Determine Watts per Square Inch required in your application.

Step One: Establish a baseline: Before setting up a test protocol, identify the basic performance characteristics you are looking for from the heater in your application. These typically include operating temperature, ambient conditions for the application and time required to reach the desired operating temperature.

Step Two: Recreate the environment: As you set up your testing area, make sure to consider the actual operating environment and try to replicate that as closely as possible. For example, make sure that your test area includes adequate air-flow if the application is used in an exposed environment, or conversely, that an insulated environment is used if the heater is to be in an enclosure. Incorporate insulation, substrates and other fixtures or objects that might influence the thermal properties of the heater.

Step Three: Gather Test Equipment: At this point, it is not always necessary to have an exact prototype made to fit your application – function is paramount. The basic equipment needed to evaluate watts per square inch include:

- Variable Power Supply – Required to “dial in” the required voltage.

- Digital Multi Meter – To measure initial resistance of the heater

- Temperature measuring devices – can also be Digital Multi Meters with thermocouple if so equipped – needed to measure surface temperature of heater and object(s) to be heated.

- Heating Element – choose the type depending on estimated maximum operating temperature, flexibility requirements, etc. Also, get the size that most closely represents the size that will be needed, if known. Get a lower voltage sample heater (48V or less) so that you can carefully increase the voltage beyond the design voltage of the heater. This allows you to exceed the design watt density of the sample, which may be required in your application.

Step Four: Test to find the required Watt Density:

NOTE: NEVER LEAVE HEATER OR TEST AREA UNATTENDED WHILE HEATER IS OPERATING!

- Make a note of the sample heater’s dimensions and initial resistance, as well as ambient temperature.

- Incorporate the heating element as required in your application.

- Place one thermocouple on surface of heater, the other where you would like to measure the performance in the application.

- Place Variable Power Supply in the OFF POSITION and hook up the heater wires.

- Put the Variable Power Supply on its lowest setting, turn on and note the input voltage.

- Allow heater to stabilize and note temperatures.

- SLOWLY increase Voltage incrementally until desired temperature is reached and stabilizes.

- Note final input Voltage and Amperage (if available).

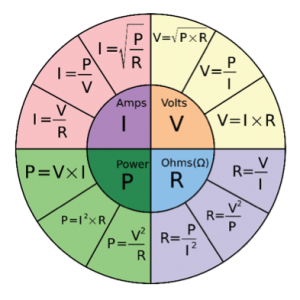

Step Five: Calculate the required watt density in your application using the following formula:

WPSI = / total square inches in the heater.

You now have the information required to determine the basic heater performance requirements. It is now time to contact your Applications Engineer to discuss your findings, finalize your heater options and move to the application specific prototyping stage. If you would like to discuss your application requirements further, please call to speak to one of our Application Engineers at 864-295-4811.