Kapton Heaters: The Versatile and Efficient Heating Solution for Any Application

Introduction

When it comes to heating solutions, you need a solution that is both versatile and efficient. That’s where Kapton heaters come in. These heaters are made from Kapton, a type of polyimide film that is known for its durability and high-temperature resistance. Kapton heaters are used in a wide range of applications, from aerospace and defense to medical and laboratory equipment. In this article, we’ll explore the benefits of Kapton heaters, how they work, and why they are becoming a popular choice for heating solutions.

What are Kapton Heaters?

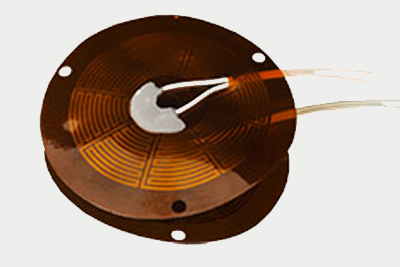

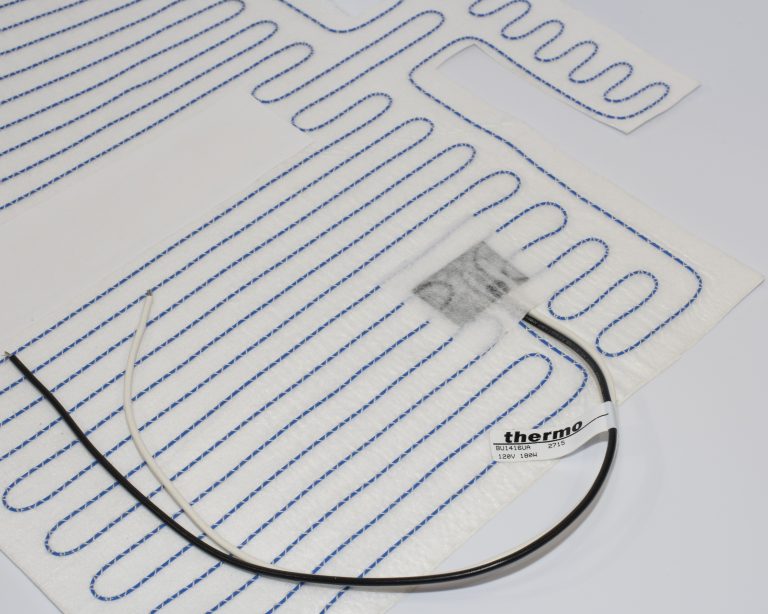

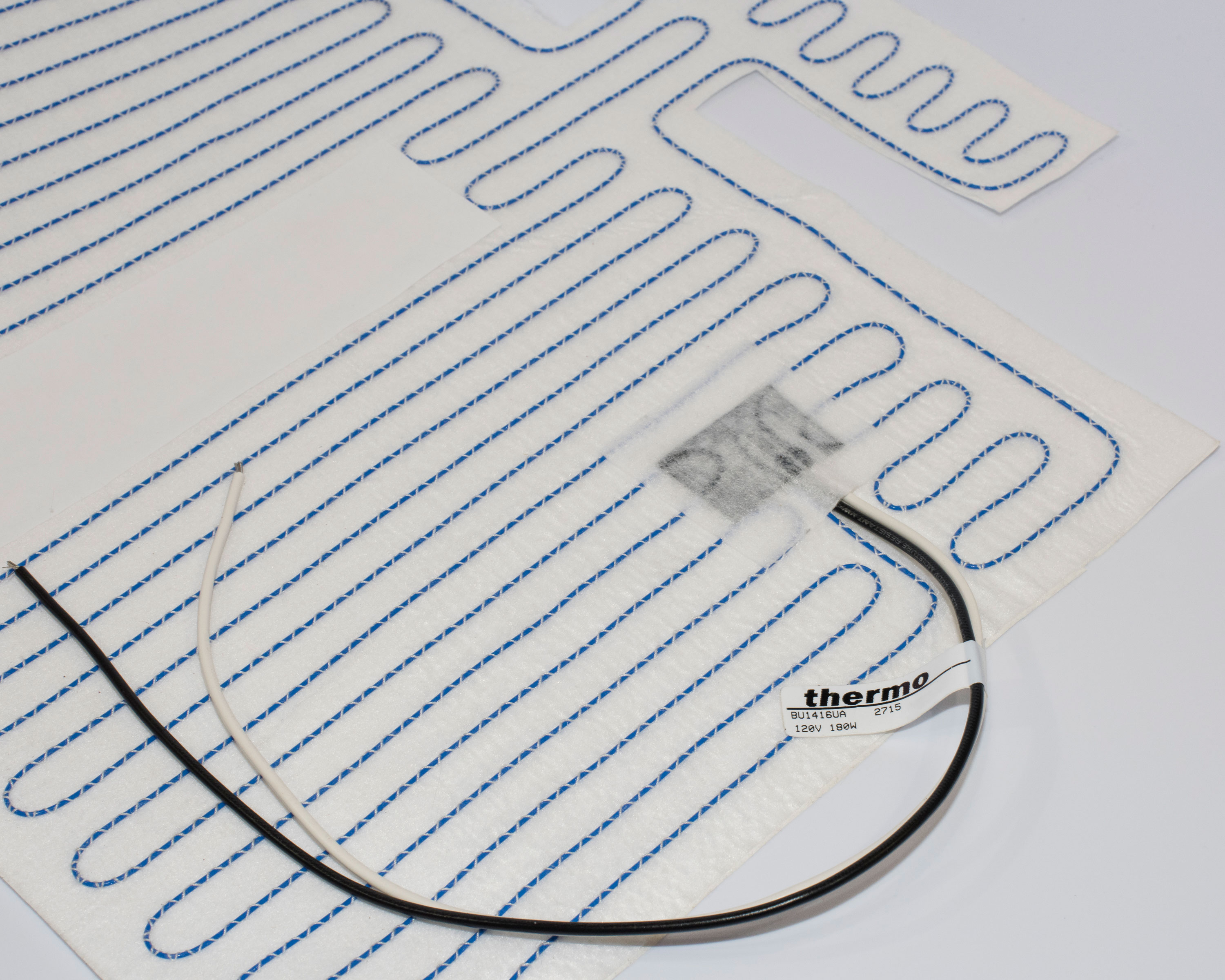

Kapton heaters are flexible and lightweight heating solutions that are made from Kapton film. This type of film is known for its high-temperature resistance, making it an ideal material for heating applications. Kapton heaters typically consist of a resistive heating element, which is sandwiched between two layers of Kapton film. The entire assembly is then coated with a layer of silicone or epoxy, which provides additional insulation and protection.

Kapton heaters can be customized to fit a wide range of applications. They can be designed in different shapes and sizes, and the heating element can be placed in different locations within the assembly. This flexibility makes Kapton heaters an ideal choice for heating applications where traditional heating solutions are not suitable.

How do Kapton Heaters Work?

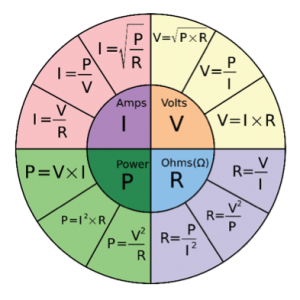

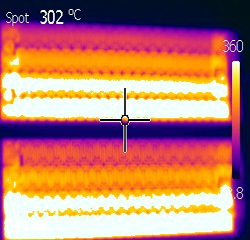

Kapton heaters work by converting electrical energy into heat energy. When an electrical current is applied to the heating element, the element heats up and radiates heat outward. Because Kapton film is an excellent insulator, the heat is directed to the object being heated, rather than being lost to the surrounding environment.

One of the key advantages of Kapton heaters is their ability to distribute heat evenly across the entire surface of the element. This means that the entire object being heated is warmed uniformly, without the hot spots and cold spots that can occur with other heating solutions.

Benefits of Kapton Heaters

- High-temperature resistance: Kapton heaters are known for their high-temperature resistance, making them an ideal choice for applications where traditional heating solutions may fail.

- Lightweight and flexible: Kapton heaters are lightweight and flexible, which means that they can be easily molded and shaped to fit a wide range of applications.

- Customizable: Kapton heaters can be customized to fit the specific requirements of your application, ensuring that you get the heating solution you need.

- Efficient: Kapton heaters are highly efficient, directing heat to the object being heated rather than being lost to the surrounding environment.

- Durable: Kapton heaters are designed to be durable and long-lasting, withstanding harsh environmental conditions and repeated use.

FAQs

Q: What are some common applications for Kapton heaters? A: Kapton heaters are used in a wide range of applications, including aerospace and defense, medical equipment, laboratory equipment, and semiconductor manufacturing.

Q: Can Kapton heaters be used in outdoor applications? A: Yes, Kapton heaters can be designed to withstand a wide range of environmental conditions, making them suitable for outdoor applications.

Q: Are Kapton heaters safe to use? A: Yes, Kapton heaters are designed to meet stringent safety standards and regulations. They are typically constructed with materials that are resistant to fire, moisture, and corrosion, ensuring that they can be used safely in a wide range of applications.

Conclusion

Kapton heaters are a versatile, efficient, and customizable heating solution that can be adapted to a wide range of applications. Their high-temperature resistance, lightweight design, and customizable features make them an ideal choice for heating applications where traditional solutions may not be suitable. Whether you’re in the aerospace and defense industry or need a heating solution for medical or laboratory equipment, Kapton heaters can provide the durability and efficiency you need.

In conclusion, Kapton heaters offer a range of benefits that make them an increasingly popular choice for heating solutions. From their high-temperature resistance and even heat distribution to their customizability and durability, Kapton heaters are a reliable and efficient solution for any application. If you’re in the market for a heating solution that can meet your specific needs, be sure to consider the versatility and efficiency of Kapton heaters.