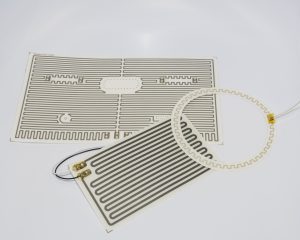

Polymer Thick Film Heaters (PTF)

Polymer Thick Film Heating Elements are manufactured using state-of-the-art screen printing equipment, and are designed using a variety of specialty conductive inks and substrates. Ink and substrate combinations are determined according to the end-use application and design requirements. This general style of heater – the PTF Heater – is divided into the following subcategories:

Standard Resistance

Self Regulating (PTC)

High Temperature Thick Film

HRT – High Resistance Technology

Polymer Thick Film Heaters can easily be designed to accommodate a variety of components such as thermostats, thermal fuses, thermocouples, thermistors, RTDs, or specialty wiring harnesses.

thermo’s Polymer Thick Film heaters have been safety tested and approved, and they are UL recognized under the UL file number E251285.

Standard Resistance Flexible Heater

A Standard Resistance PTF heater is manufactured using a high grade, low shrinkage polyester substrate in sheet or roll form. A polymeric, silver-based paste is screen printed onto the polyester in the desired circuit pattern. This sheet or roll is then oven dried to cure or “set” the element. The circuits are then terminated according to customer requirements, and pressure sensitive adhesive (PSA) applied.

Features:

• Cost-effective for mid to high volume applications

• Optimal energy efficiency

• Thin, flexible construction

• Superior heat transfer

• Uniform heat distribution

• Unlimited heater configurations.and connections

• Maximum continuous use temperature 105° Celsius.

High Temperature Thick Film

High Temperature Thick Film heating elements are similar to Standard Resistance heaters in both manufacture and construction, but utilize higher temperature inks, substrates and bonding materials. The result is a moderately priced flexible heating element with the benefits of Standard PTF heaters, but also with an increased maximum surface temperature of 130° Celsius.

HRT – High Resistance Thick Film

Engineers often encounter issues when designs require heating elements with high resistance in very small areas. A traditional solution to this problem has been for the heating element manufacturer to use very fine, delicate resistance wire, leading to premature failure, low production yields and high unit cost. Often the required resistance is so high that none of the traditional technologies will provide a solution.

Using our core technology of polymer thick film heating elements, Thermo has developed HRT – high resistance technology elements that surpass the resistance density of the traditional product offerings. Because the elements use our polymer thick film technology, heating element costs are much lower than the traditional elements and are available in multiple configurations and design options.