thermo Heating Elements, LLC is pleased to announce that after months of development and testing, the new innovative product line Ultraflex is now UL rated.

thermo Heating Elements, LLC introduces UltraFlex to its product line

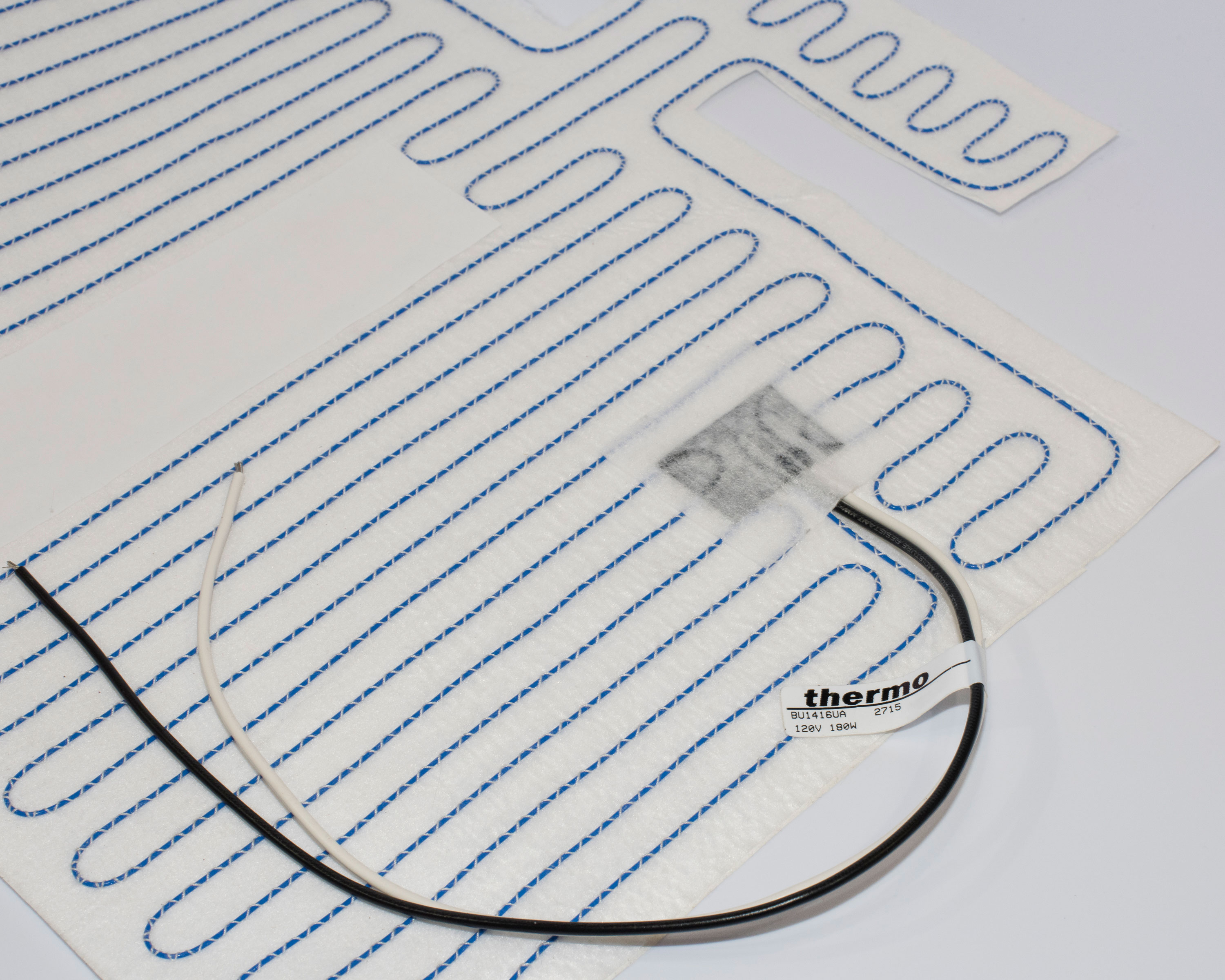

thermo Heating Elements, LLC is excited to annouce the addition of UltraFlex to its product line. UltraFlex is a cost-effective, resilient, and highly flexible heating system that can be designed in a wide range of shapes and sizes and fabricated to very precise specifications. While customizable for use in a variety of industries, UltraFlex heaters are typically manufactured using multi-stranded, insulated corrosion resistant wire, resulting in a heater with unparalleled durability, flexibility, and softness. UltraFlex is a product able to withstand continuous flexing and applicable to multiple flexing applications. It can also be molded to best fit the final product as well as be laminated or layered to the customer’s specifications. UltraFlex has a maximum operating temperature of 302F (150C) and is available in sizes up to 28″ X 44” with a maximum watt density of 15 watts per square inch and voltages up to 300VAC. In order to meet the high demands of today’s engineers, the UltraFlex product line has been created to combine design flexibility with rapid prototyping, providing highly customized solutions to the most challenging situations. Please contact our sales engineers for more information.

thermo Heating Elements, LLC

273 Langston Road Piedmont, SC 29673

PH: 864-295-4811

F: 864-295-4899

thermo-llc.com

thermo Develops High Temperature Ceramic Heaters

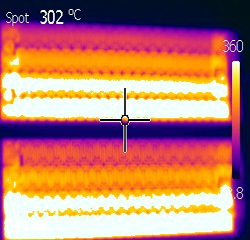

thermo Heating Elements, LLC has set a precedent in the industry for continuing to develop new technologies to meet customer demands. thermo’s latest technology, the Ceramic Infrared heating element, was created in response to a need for a higher temperature heater with maximum efficiency that still maintains durability and design flexibility. These heaters are capable of transferring up to 90% of their input as radiant energy, and maximum efficiency is reached when the emitted wavelength and the absorption spectrum of the material to be heated are optimized.

Ceramic elements are used when high temperatures are required, fast responses or temperature gradients are needed or products need to be heated in certain areas in a targeted way. Typical operating temperatures range from 300°C to 700°C (572°F – 1292°F) producing infrared wavelengths ideal for caramelization of breads, warming and heating of foods, curing of coatings, and softening or welding of plastics.